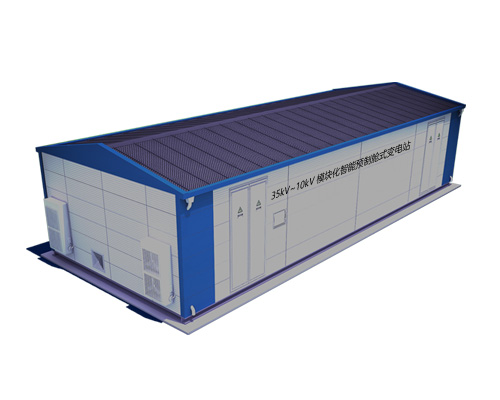

The 35kv24kv12kv modular prefabricated cabin substation can be configured as a container switch station, photovoltaic booster station, primary equipment room, and secondary equipment room. The construction and installation are fast and the land is saved. It can be built in multiple layers, generally up to 3 floors.

Widely used in photovoltaic power stations, wind power stations, substations, power plants, user projects, energy storage projects,

The 35kV~10kV modular prefabricated cabin substation is a system that integrates transformers, multi-circuit high-voltage switch systems, reactive power compensation devices, insulated busbars, integrated substation automation systems, communications, telecontrol, metering, and DC power supply units. , Reliability, easy maintenance, and integration principles are integrated and installed in a heat-insulating, fire-proof, anti-theft, moisture-proof, anti-small animal, five-sided ventilated, fully enclosed, and movable steel structure box. It is suitable for the construction and transformation of urban and rural 10Kv~35Kv integrated substations, small and medium-sized substations (distribution) substations, and industrial and mining enterprise substations. Because it goes deep into the load center, reduces the power supply radius, and improves the quality of power supply, it is especially suitable for the transformation of urban power distribution networks. It is known as the "target mode of substation construction in the 21st century." It complies with the standards of the State Grid Corporation of China, the new rural electrification standard system and the electrification implementation outline. It has truly realized the leap from building a substation in the traditional way to buying an integrated substation!

Features

■ The standard design of 35kV~10kV modular prefabricated substation covers an area of only 230 square meters. Compared with conventional substations, it can save 60%~80% of the area, which is in line with the national land saving policy.

■ The electrical equipment used can effectively reduce the cost of the product; the electrical equipment is installed indoors and will not be affected by external factors, and the operation and maintenance costs are greatly reduced; the all-metal structure shell is adopted, and all components are treated with anti-corrosion and maintenance. Very small quantity, long service life and low energy consumption;

■ Adopt an integrated construction plan. The conventional design plan has been constructed many times. The design and construction are carried out according to the ready-made plan, and the amount of local adjustment is very small. Various functional modules such as: inlet module, outlet module, transformer and The protection module only needs to be called directly, and the production cycle is relatively short. The construction period is shortened to 3 months, and the construction period of a conventional substation takes at least about 1 year. It is really better to buy a station to build a station.

■ The prefabricated integrated substation has almost no impact on the environment, because the amount of pre-construction is very small, except for the structure, all construction work is carried out indoors, and the noise and electromagnetic radiation during operation are shielded in the metal layer. Moreover, the shell structure is made of metal components, and the service life is much longer than that of brick-concrete and cement structures, and all parts can be recycled and reused.

Conditions of Use

■ Use of production: outdoor;

■ Altitude: ≤ 3000m;

■ Ambient temperature: -45℃ ~ +45℃, the highest daily average temperature does not exceed 35℃;

■ Wind speed: ≤ 35m/s;

■ Ground inclination: ≤ 5;

■ Sunlight radiation: ≤ 1000W/m2;

■ Relative humidity: daily average ≤ 95%, monthly average ≤ 90%;

■ Ice coating thickness: 10mm;

■ Seismic fissure: no more than 8;

■ Foundation: the characteristic value of the foundation bearing capacity Fak = 150kpa, without the influence of groundwater;

■ There is no explosion hazard, fire, chemical corrosion and severe vibration at the installation site.

■ Please contact our technical department if it exceeds the provisions of these conditions of use.

Prefabricated cabin structure and technical requirements

The overall structure design of the cabin should meet the requirements of current national standards and design codes, and combined with the actual project, rationally select materials, structural schemes and structural measures to ensure that the structure meets the requirements of strength, stability and rigidity, and waterproof and fireproof during transportation and installation. , Anti-corrosion, durability and other design requirements.

The installation and arrangement of equipment in the prefabricated cabin shall meet the requirements of relevant regulations.

The bidder shall provide the structural design plan of the prefabricated cabin, the selection of interior and exterior wall materials, the selection of electrostatic floor, the specific design plan of air conditioning and ventilation, as well as the internal and external renderings and photos of the prefabricated cabin.

1. The importance factor of the cabin shall be designed according to the safety level of the structure, the design service life shall be considered as 25 years, and the protection level of the cabin shall not be lower than the requirements of IP55 specified in GB/T 4208-2008.

2. The cabin body should adopt a steel structure system, and the roof should adopt a cold-formed thin-walled steel purlin structure. Flame-retardant and heat-insulating panel materials should be made of materials that are not easy to burn, have low water absorption, and have good heat preservation and heat insulation effects.

3. The cabin body should adopt a steel column structure, and the main rigid frame can be a solid web rigid frame with constant cross section. The spacing between columns should be determined according to the longitudinal column distance, force condition and installation conditions of the box room. When the inter-column support is not allowed, other forms of support can be set; when any support is not allowed, the longitudinal rigid frame can be set. Rigid tie rods should be arranged along the entire length of the cabin at the turning points of the rigid frame (side column tops and roof ridges).

4. The lifting point of the cabin body should be set at the bottom of the prefabricated cabin. The lifting point should be determined according to the load distribution of the cabin equipment and the number of lifting points after detailed calculation to ensure safety and reliability.

5. The self-weight of the structure, the concentrated load for inspection and repair, the snow load on the roof and the ash load, etc. shall be adopted in accordance with the current national standard "Building Structure Load Code" GB 50009, and the suspended load shall be taken according to the actual situation.

6. The wind load standard value of the cabin shall be calculated in accordance with the provisions of Appendix A of the "Technical Specification for Portal Frame Light Steel Structures" CECS102.

7. The earthquake action should be calculated in accordance with the current national standard "Code for Seismic Design of Buildings" GB 50011.

8. The cabin frame should be welded as a whole to ensure sufficient strength and rigidity. The cabin should not be deformed or damaged during lifting, transportation and installation. The deformation of the cabin steel structure of the steel column structure shall be calculated in accordance with the requirements of CECS102 in the "Technical Specification for Portal Frame Light Steel Structures".

10. The installation of the cabin door should meet the requirements of equipment transportation and inspection in the cabin. Class B fire doors should be adopted. The combustion performance and fire resistance of other building components should meet the requirements of Article 3.2.1 of the "Code for Fire Protection Design of Buildings" GB50016. Use fans and air conditioners to achieve ventilation.

11. The opening of the cabin door meets the requirements of the design fire protection code for thermal power plants and substations (GB50229-2019). The door size meets the equipment handling requirements. In principle, the door opening is set at the end of the long side of the cabin, and the door opening position should be coordinated with the general layout.

12. The cabin body should adopt a double-sloping roof structure, and the roof slope should not be less than 5%. The roof slope can be appropriately increased in northern areas to prevent water and snow accumulation. The roof panel should be made of light-weight, high-strength, corrosion-resistant, and waterproof materials, and the middle layer should be made of non-flammable, low water absorption, low density and thermal conductivity, and a certain strength insulation material.

13. The cabin roof can adopt two methods: organized drainage and natural dispersal. When using organized drainage, the drainage channel and downspout are supplied with the cabin body and installed on site. The downspout should be built-in. For cold areas, scattered discharge can be used. The air-conditioning drain pipe should be covered with a dark coating or a slot box.

14. The bottom of the cabin can be made of patterned steel plates or epoxy resin partitions. The floor of the cabin should adopt ceramic anti-static raised floor, and the steel bracket of the raised floor should be fixed on the bottom of the cabin. The height of the anti-static raised floor should be 200~250mm, which should be convenient for cable laying and maintenance.

15. The cabin body and the foundation should be firmly connected, and should be welded to the embedded parts of the foundation. The joint between the cabin body and the foundation should be sealed with weather-resistant silicone glue to prevent moisture from entering.

16. The 35kV switchgear is placed in the box along the length of the prefabricated cabin. Two channel steels (above #8) are arranged on the bottom plate of each row of screen cabinets, which are welded to the bottom plate as the installation basis for the switchgear. The switchgear chassis is through anchor bolts. Fixed with channel steel, bolt size M12 and above.

17. The cabin structure must take effective anti-corrosion measures, and the structure should be considered to facilitate inspection, cleaning, painting and avoid water accumulation. After the anti-corrosion treatment of the parts, after the neutral salt spray test for at least 196 hours, there should be no metal matrix corrosion.

4.9.4 Configuration requirements for electrical and auxiliary facilities of prefabricated cabins

1. Complete safety protection, fire alarm and video monitoring measures should be installed in the prefabricated cabin, and lighting, maintenance, grounding, etc. should be installed at the same time to ensure the safe operation of the prefabricated cabin equipment and personnel inspection requirements.

2. The cabin lighting should meet the "Technical Regulations for Lighting Design of Thermal Power Plants and Substations" DL/T 5390, "Architectural Lighting Design Standards" GB50034, "Low-Voltage Power Distribution Design Code" GB50054, "Fire Emergency Lighting" GB17945 and other relevant regulations and specifications Requirements.

3. The design of the fire detection and alarm system in the prefabricated cabin and the fire control equipment and its functions shall comply with the current national standard "Code for Design of Automatic Fire Alarm System" GB50116. The cabin shall be equipped with a fire alarm and smoke detection device. The fire alarm smoke detection device adopts a ceiling arrangement. The cabin should be equipped with portable fire extinguishers and placed at the door. The level and number of fire extinguishers should be configured according to the fire hazard category as medium-hazard. In the case of ensuring safety and reliability, a fixed gas fire extinguishing system can be installed. The bidder shall cooperate to pass the acceptance by the local fire department.

4. Air-conditioning, fans and other heating and ventilation facilities should be installed in the cabin to meet the requirements of the equipment operating environment. The temperature in the cabin should be controlled within the range of (5~30)℃ under normal working conditions.

5. The cabin shall be equipped with mechanical ventilation devices, and a ventilation loop shall be formed in the cabin. When fan ventilation is used, the air duct should have dust and waterproof measures, and positive pressure ventilation should be adopted to prevent dust from entering the cabin during ventilation.

6. The relative humidity in the cabin is 45% to 75% to ensure that the equipment does not appear to be condensed under any circumstances.

7. Video surveillance should be installed in the cabin, and 2 Hikvision network cameras should be installed in the cabin to connect to the project's video surveillance system.

8. At least one distribution box is installed in the cabin.

9. An emergency escape door should be provided in the cabin, which can be activated in an emergency under any circumstances. The remaining doors should meet the requirements of relevant regulations.

4.9.5 Cable interface requirements for prefabricated cabins

1. The cables are led directly from the cabinets in the cabin to the outside of the cabin, and there is no centralized cable interface cabinet.

2. The prefabricated cabin adopts the lower wiring method. The bottom of the cabin needs to be equipped with a control cable trough box or mezzanine. The height should be 200-250mm. The cable laying and cable arrangement configuration follow the conventional cable laying regulations.

3. The prefabricated cabin should be reserved for cable import and export in accordance with the requirements of civil engineering design and coordination with primary equipment;

4. The equipment interface between the external prefabricated cable and the box, as well as the box, should meet the enclosure protection class IP54.

4.9.6 Grounding and anti-interference requirements for prefabricated cabins

1. The prefab cabin and its internal equipment complete work grounding, protective grounding, lightning protection grounding, and anti-static grounding in the station. The grounding system of the prefabricated cabin shall meet the requirements of GB/T 50065-2011 "Code for Grounding Design of AC Electrical Installations".

2. The grounding trunk line should be hidden in the prefabricated cabins, and each prefabricated cabin should be equipped with 2~4 temporary grounding terminals 300mm away from the raised floor. The grounding terminals should be copper bolts with a diameter of not less than 12mm. An obvious primary grounding mark shall be set at the connection point.

4.9.7 Material requirements for prefabricated cabins

1. The prefabricated cabin wall adopts thermal insulation composite wall. The prefabricated cabin wall consists of external walls (Jinbang board or facing FC board), polyethylene moisture-proof sealing film, thermal insulation materials, dragon skeleton, and internal walls (aluminum-plastic panels or sandwich panels). Core board) and other materials.

2. The cabin material of steel column structure should be composed of painted FC board, polyethylene moisture-proof sealing film, heat preservation material, Ou Song board, structural members, aluminum-plastic board and other materials from the outside to the inside.

3. The material of the internal structure is required to have good compatibility with the welding (connection) of the main body of the box, with high reliability, and the surface is beautiful and does not rust.

4. The thermal insulation material should be rock wool or polyurethane, and the thickness of the thermal insulation material should be determined by thermodynamic simulation calculation.

4.9.8 Requirements for interior and exterior decoration of the cabin

1. The name of the prefabricated cabin is sprayed on the front of the exterior of the cabin, and the group logo is printed on the upper left corner. The name of the prefabricated cabin is named according to the function, and should be marked in the center at about 2/3 of the total height of the bottom of the outer wall of the prefabricated cabin in the length direction. The font is black and bold, and the font height is 500mm. The LOGO of the integrated manufacturer is marked on the lower left corner of the white area on the lower part of the outer wall in the width direction of the prefabricated cabin, and the height is not more than 150mm.

2. The appearance and color of the screen cabinets in the cabin are uniform, and the position, font, and height of the screen cabinet name and manufacturer's name should be consistent.

4.9.9 Layout requirements for prefabricated cabin screen cabinets

The 35kV switchgear in the prefabricated cabin shall be arranged in a single row.